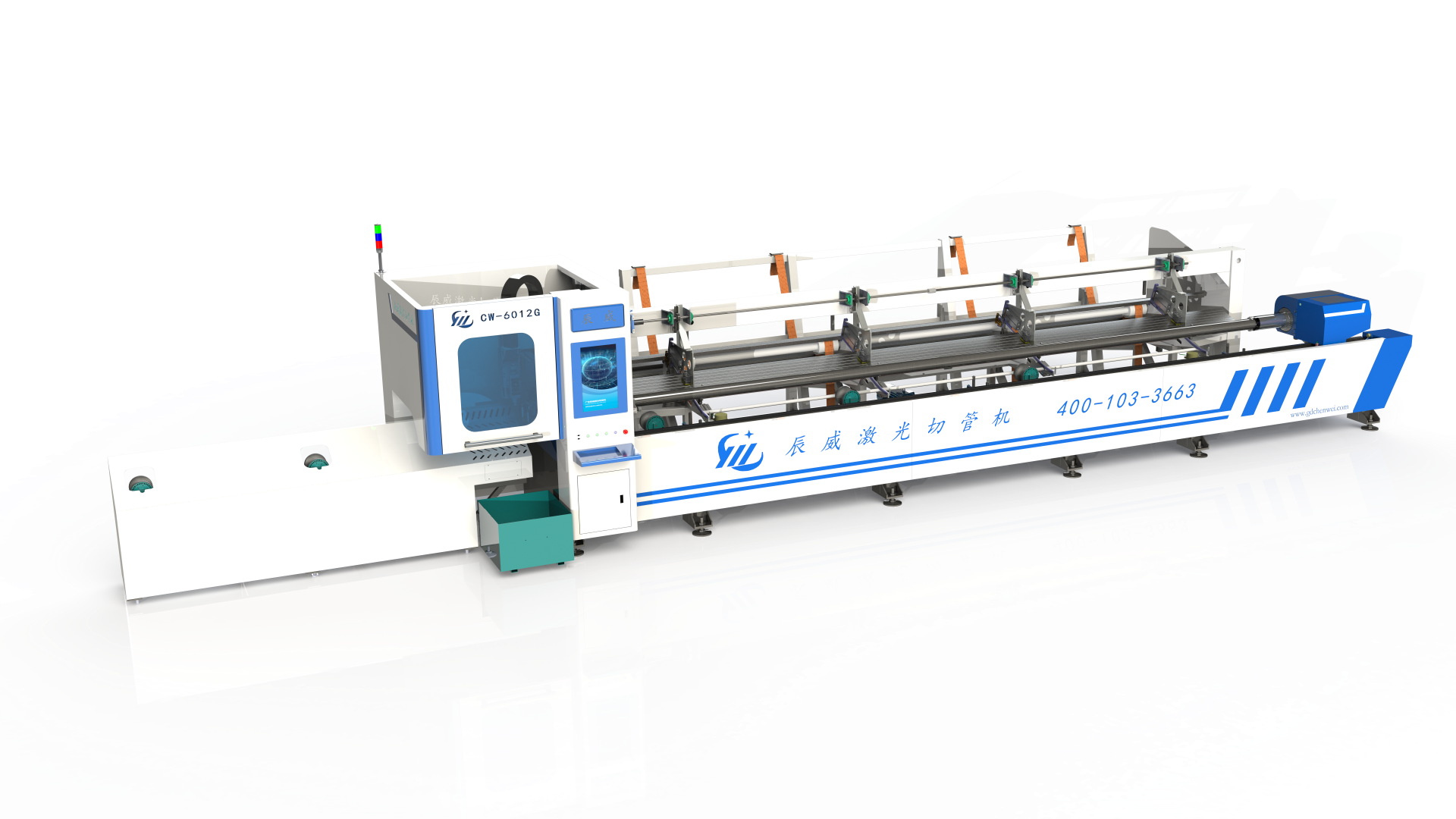

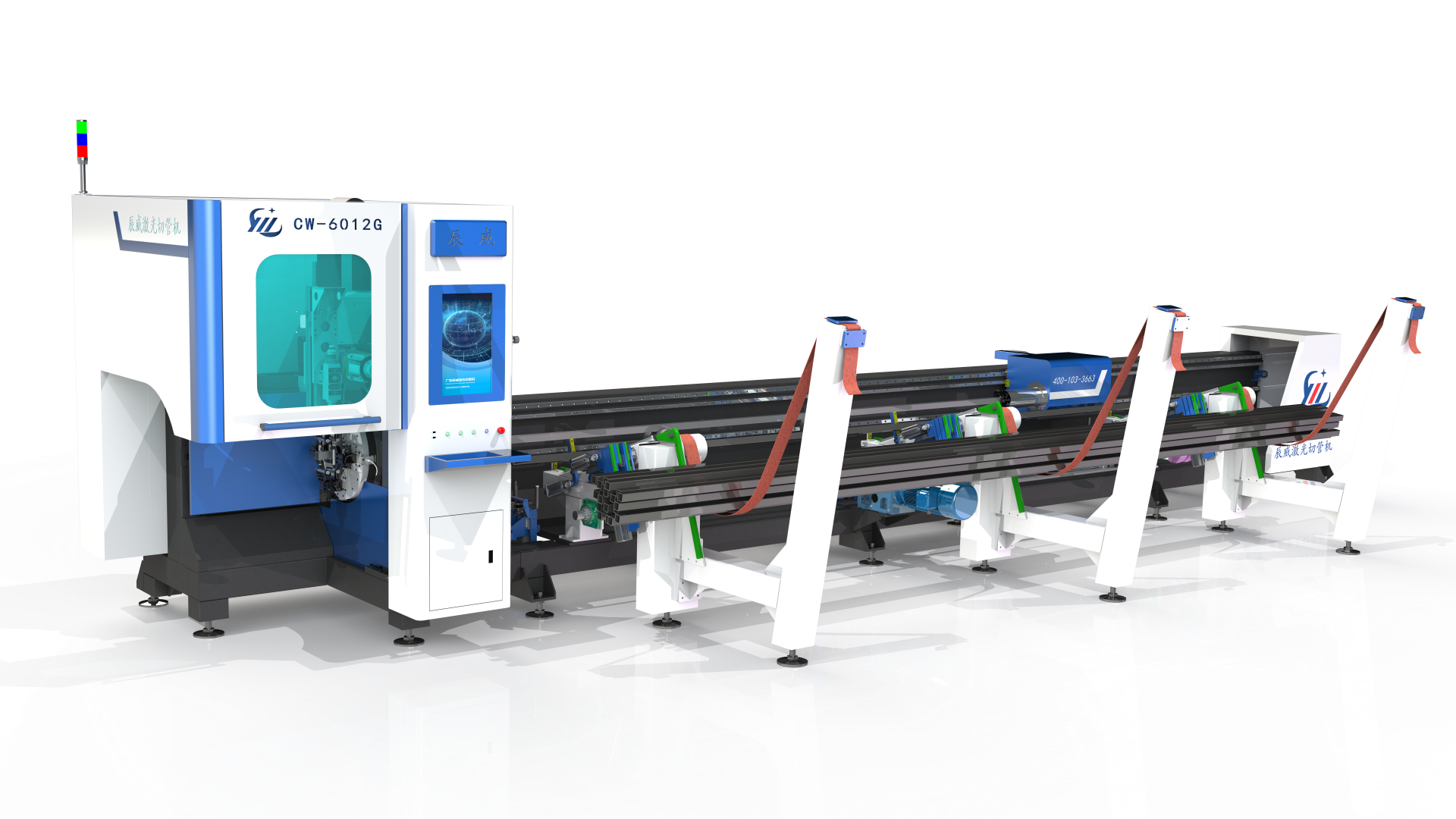

Fiber Laser Robot 3D Cutting System

- Commodity name: Fiber Laser Robot 3D Cutting System

Consultation Hotline:

400-103-3663

- Product Description

-

Product Features

1. Fiber Laser

High photoelectric conversion efficiency, energy-saving, maintenance-free operation, high beam quality

2. Offline Programming System (Optional)

3D model import, improves programming efficiency, reduces downtime debugging, and saves costs;3. Suitable for Various Materials

Fast cutting speed, high quality, capable of cutting high-reflectivity materials such as aluminum and copper.Application Industries

Automotive parts, motorcycle parts, sports equipment, medical devices, electric vehicles, tricycle parts, daily hardware, tool products, children's vehicles, baby strollers, metal furniture, school supplies, and other industries.

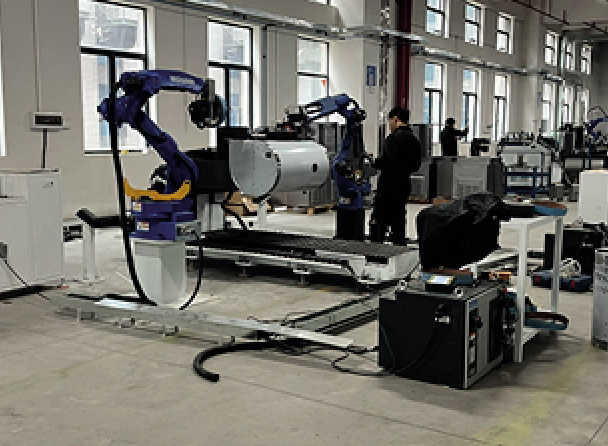

Stamping Robot System

Stamping robots replace repetitive and high-risk manual labor. During the stamping line production process, the current equipment status, output, and efficiency can be intuitively viewed on the LED display. Production quantity can be set according to actual needs. All equipment on the entire line is linked by centralized control: if any link encounters an error, the stamping line will immediately stop automatically, protect, alarm, and display the specific equipment and reason, facilitating troubleshooting and resolution.

Palletizing Robot System

Palletizing robots are a form of industrial robot application that organically integrates mechanical technology with computer programs, significantly improving modern production efficiency. These robots operate flexibly and precisely, with fast speed, high efficiency, strong stability, greatly saving labor, and effectively saving space.

Spraying Robot System

The spraying robot consists of the main body, peripheral equipment, and control cabinet, capable of independent single-machine operation or multi-machine coordinated operation. By cooperating with peripheral equipment, it can perform workpiece supply, door opening assistance, and drive walking operations, thereby completing high-quality assembly line spraying. The robot has multiple setting methods and flexible layout: the internal pressure explosion-proof structure reduces gas consumption, and some can be wired in non-explosion-proof environments, reducing operating and maintenance costs.

Grinding Robot System

The grinding robot is an automated intelligent processing device, including the industrial robot body, control system, grinding tool module, and high-precision torque sensing system. This equipment uses preset processing programs and motion trajectories combined with real-time torque feedback data to dynamically adjust grinding parameters. The system can monitor contact force in real time through the torque sensor based on the wear status of the grinding tool and perform adaptive compensation, achieving high-precision and consistent grinding processing on various workpiece surfaces.

Previous Page

Previous Page