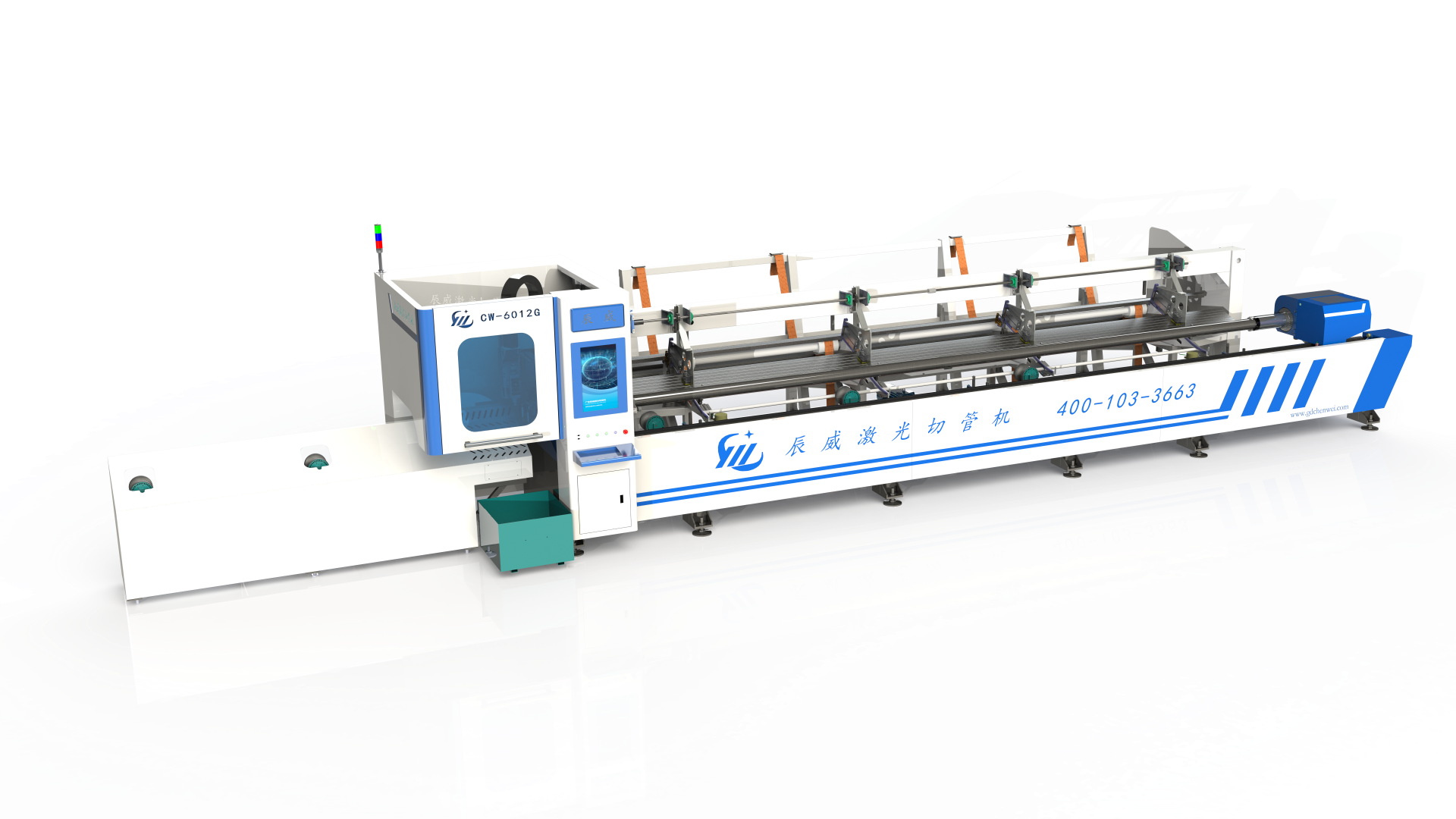

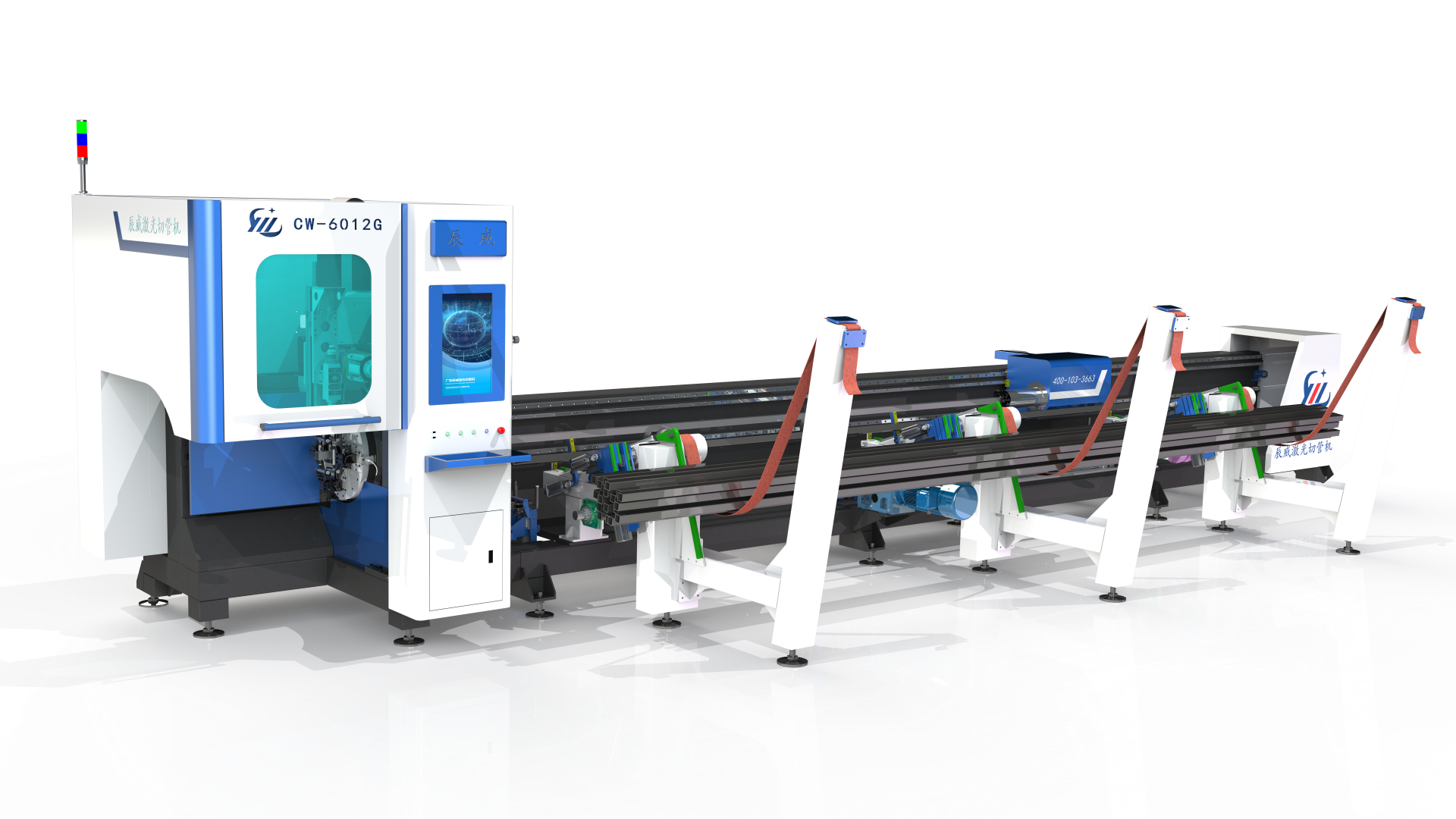

Collaborative Welding Robot System

- Commodity name: Collaborative Welding Robot System

Consultation Hotline:

400-103-3663

- Product Description

-

Technical Parameters

Serial Number Product Name Specification Brand Unit Quantity Features 1 Collaborative Robot KX950-3D/KX1300-8D/KX850-5Y Kelda Unit 1 Drag welding points, no code programming required, repeat positioning accuracy 2 Welding Torch Dedicated welding torch for collaborative robots, servo welding torch (KX1300-8D) Kelda Piece 1 Integrated Human-Machine Interface 3 Welding Power Source X350L/X500/X350SW (KX1300-8D) Kelda Unit 1 Lower heat input greatly reduces thin plate deformation 4 Wire Feeder Standard Configuration Kelda Unit 1 High-Speed Feeding 5 Welding Accessories Welding Trolley, Arc Tracking Kelda Set 1 Product Features

1. Easy to Use

Collaborative robot drags welding points, integrated human-machine interface on the welding torch requires no code programming, directly set the number of welds, matches welding processes, with optional swing and multi-layer multi-pass functions.

2. Intelligent Application

Collaborative robot uses new motion control algorithms, repeat positioning accuracy ±0.02mm, maximum working speed 2m/s; effectively suppresses jitter, improves adaptability, and makes movements smoother.3. Arc Tracking

Can collect and process arc signals to obtain the relative position between the welding torch and groove, timely correct robot path deviations, ensuring welding accuracy.4. Pulse Transition

Fine control of pulse waveform achieves one pulse one droplet transition, short arc length, high stiffness, good weld fusion, reducing welding defects such as porosity and undercut.5. Suitable for Various Materials

Built-in rich welding expert database, simple operation, freely adjustable arc shape, adaptable to different welding requirements, capable of pulse and short-circuit welding for materials such as carbon steel and stainless steel.

Previous Page

Previous Page