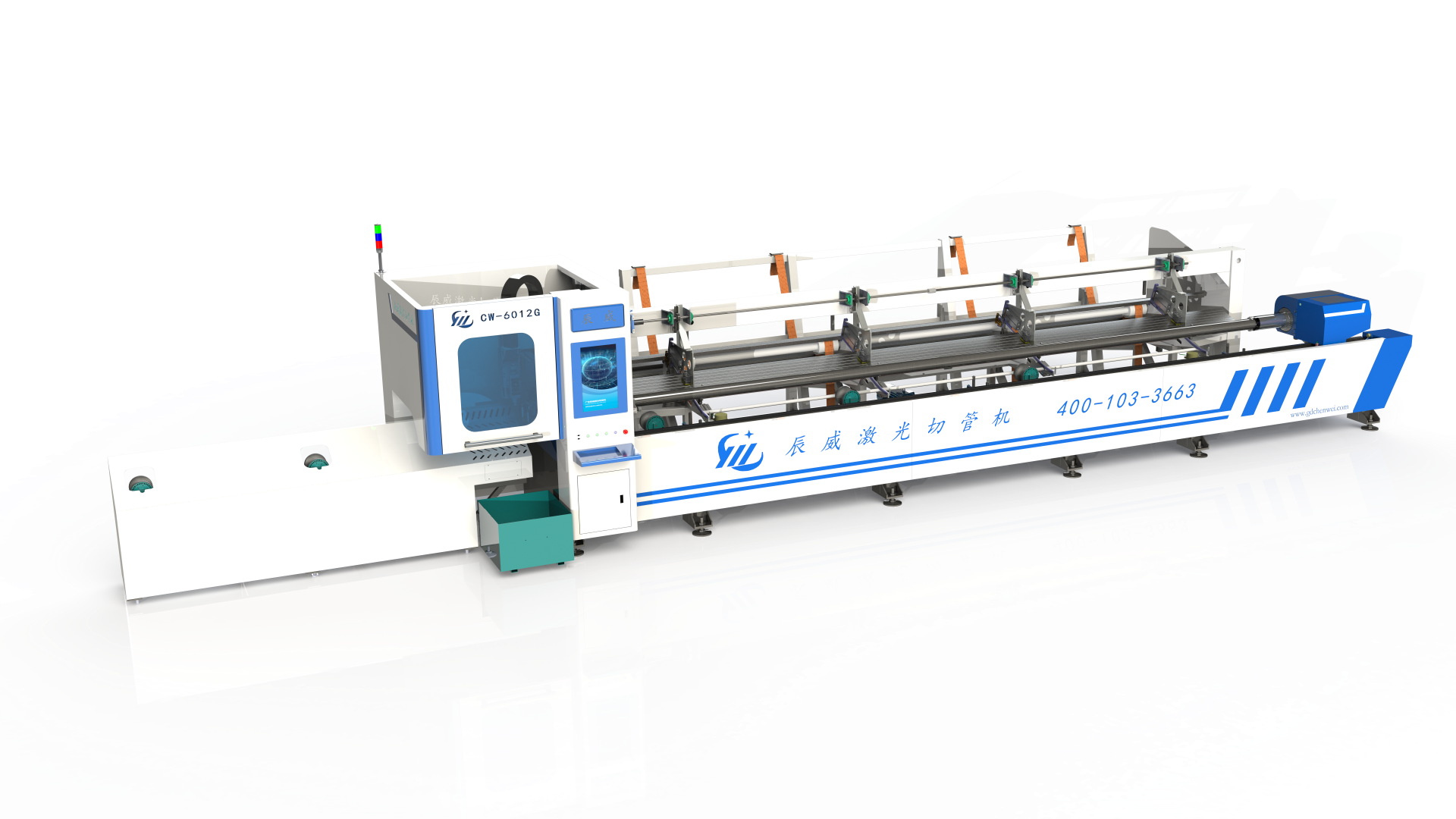

Intelligent Pipe Cutting System

Ultra-high-speed High-precision Laser Pipe Cutting Machine G Series

- Commodity name: Ultra-high-speed High-precision Laser Pipe Cutting Machine G Series

Consultation Hotline:

400-103-3663

- Product Description

-

Technical Parameters

Product Model CW-6012G CW-6016G CW-6023G CW-6028G CW-6036G Pipe Size Range 8mm-120mm 10mm-165mm 15mm-240mm 20mm-280mm 25mm-360mm Power Range 1500W~6000W 3000W~20000W Pipe Length Range ≈6200mm ≈6500mm ≈6500mm ≈6500mm ≈6500mm Repeat Positioning Accuracy 0.02mm Chuck Speed 200r/min 160r/min 120r/min 80r/min 60r/min Feeding Method Manual/Semi-automatic/Fully Automatic Machine Dimensions ≈9.5*3*2.5m ≈9.5*3*2.5m ≈9.6*3*2.5m ≈10*3*2.5m ≈10*3*2.5m Pipe Cutting Types Round pipe, square pipe, oval pipe, angle steel, groove, H-beam, special-shaped pipe, etc. Maximum Acceleration 2.0G 1.2G 1.0G 1.0G 0.8G Pipe Material for Cutting Stainless steel, carbon steel, aluminum, copper, iron and other metal materials Product Features

The bed is optimized and designed to accommodate an automatic feeding system to reduce footprint, and is treated twice with high-temperature annealing to ensure high rigidity and stability of the bed.

The rear chuck can pass through the front chuck design, with a minimum tail length of

Equipped with alloy precision external clamp self-centering pneumatic chuck, higher precision, fully sealed design of front and rear chucks for stronger reliability.

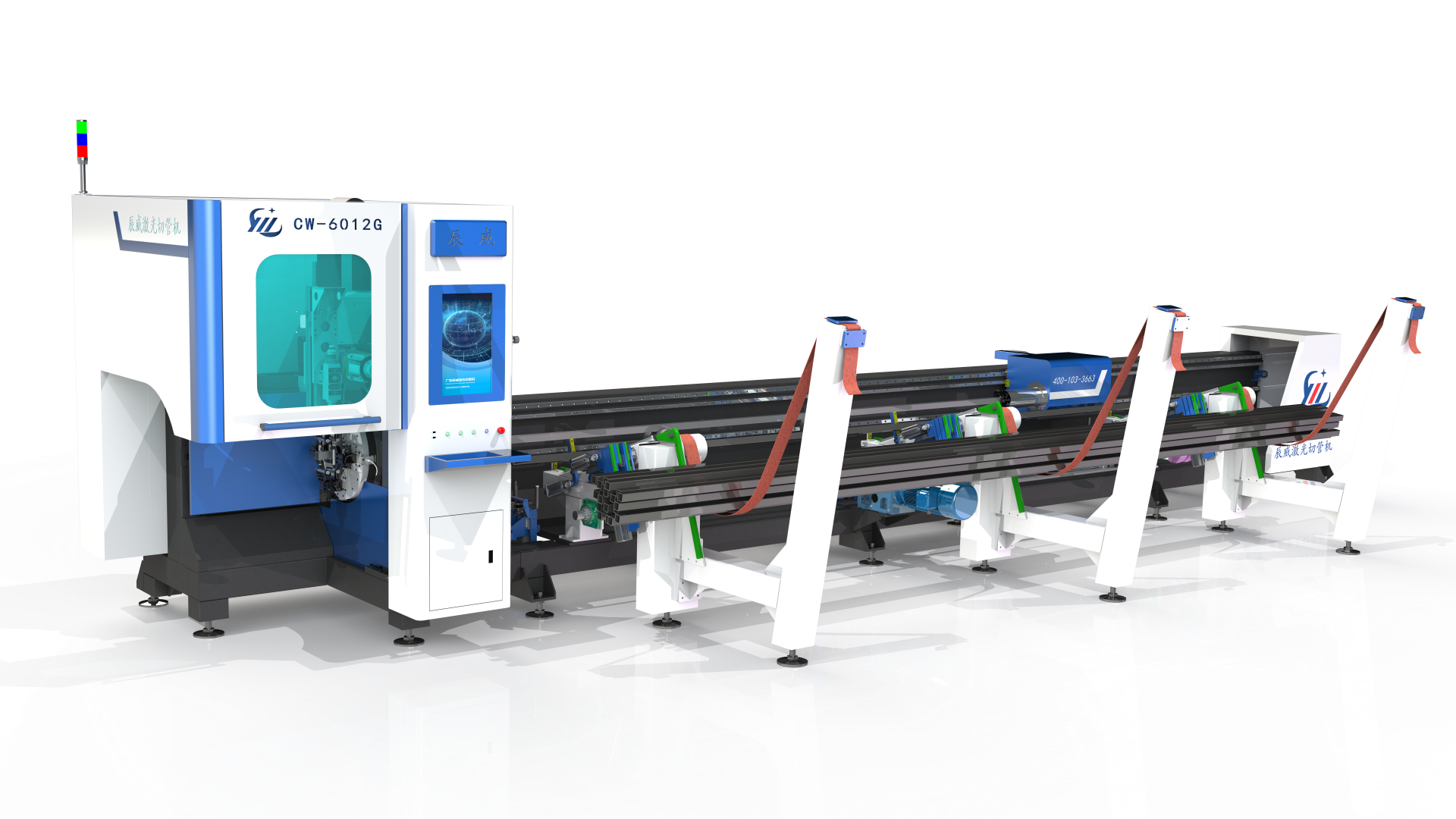

Gantry servo-controlled feeding rack effectively prevents pipe flipping, stacking, and misalignment during feeding, making feeding more stable and product changeover and debugging more efficient.

Feeding system optionally equipped with fully automatic bundle feeding and semi-automatic arranged feeding.

Speed and precision are at the industry advanced level, suitable for precision cutting in most industries.

Previous Page