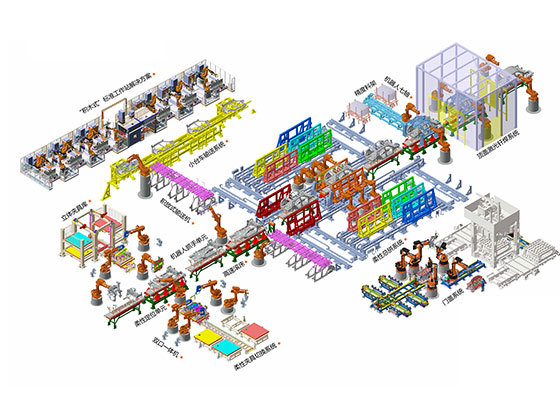

Overview of Intelligent Manufacturing System Innovation for White Body

Product Introduction

1. High-speed roller bed trolley conveyor reduces non-process time and improves the utilization rate of process equipment

2. Windmill switching mechanism enables flexible trolley switching, allowing random switching among 4 platforms, making model introduction convenient and fast

3. Standard flexible final assembly system achieves random switching, with 4 model lines and a line width of 18m

4. The main line and re-welding line use in-line circulation to reduce the number of empty trolleys returning and reduce the second-level steel platform

5. Includes modules such as side panel pre-assembly, final assembly, roof panel installation, laser, wheel cover hemming, arc welding, re-welding, punching, and online inspection

6. Quickly generate plans and corresponding process files by selecting appropriate modules according to product process

Product Parameters

| Positioning Welding Station Conveyor Cycle | 8S (Distance 6M) |

| Re-welding Station Conveyor Cycle | 5S (Distance 6M) |

| Repeat Positioning Accuracy | ±0.1MM |

| Production Mode | Random production of 4 models |

Product Advantages

| Conveying Form | Conveying Time | Single Station Equipment | 51s Single Station Welding Spot / Robot (3.5S/Spot) |

Robot Utilization Rate | Investment Difference |

|---|---|---|---|---|---|

| Trolley | 8s | Trolley + High-speed Roller Bed | 12 | 84% | Save 3 million yuan* |

| Skid | 5s | Skid + High-speed Roller Bed | 11 | 76% | — |

* Based on 800 welding spots on the main line, trolley conveying can save 4 robots and at least one welding station cost of 3 million yuan

Related Solutions