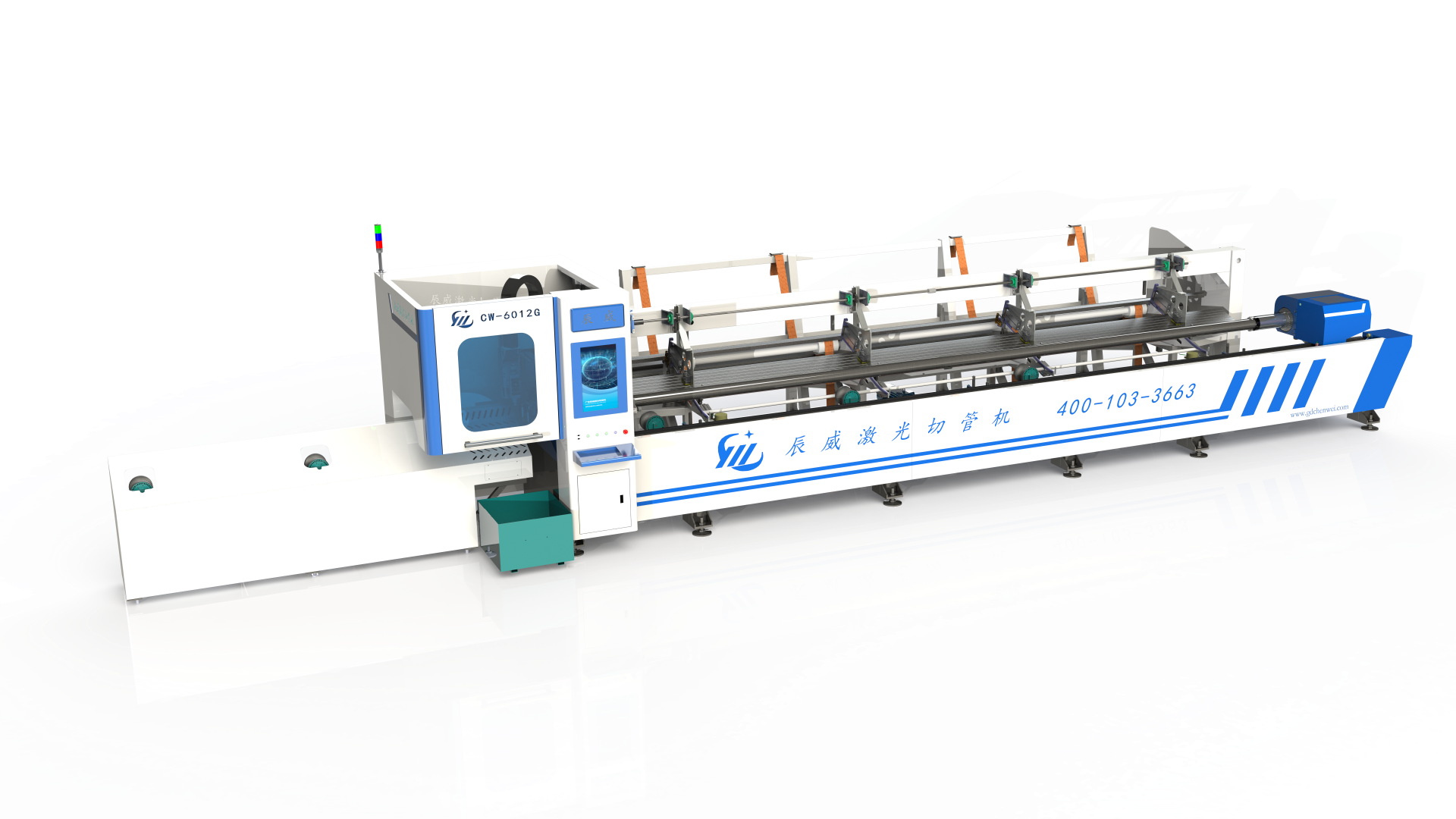

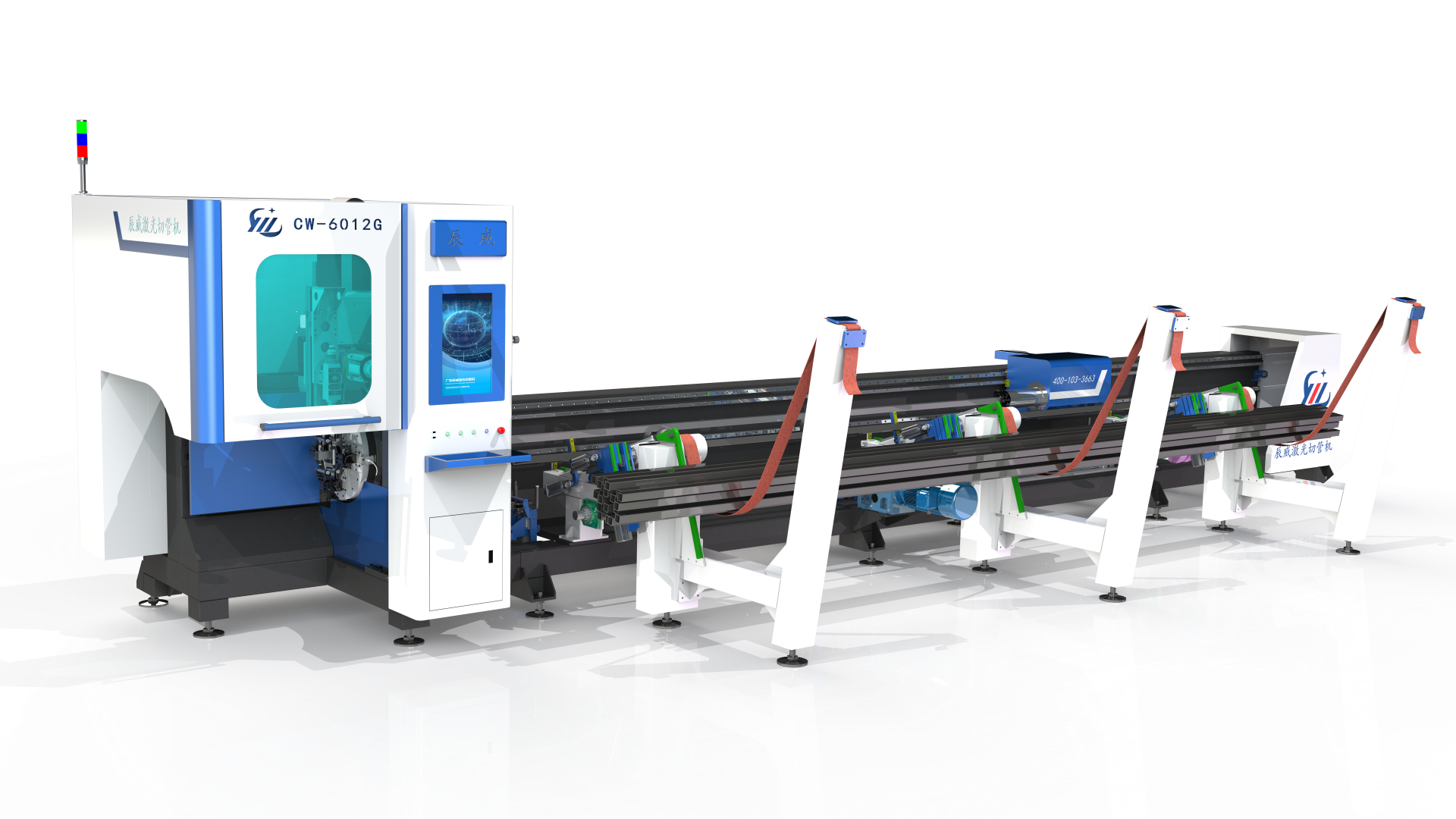

Fiber Laser Robot 3D Welding System

- Commodity name: Fiber Laser Robot 3D Welding System

Consultation Hotline:

400-103-3663

- Product Description

-

Technical Parameters

Model 1500W 2000W 3000W 6000W (Laser Arc Hybrid Welding) (LAHW) Penetration Depth (Stainless Steel) 3MM 4MM 6MM 8MM Penetration Depth (Carbon Steel) 3MM 4MM 6MM 8MM Penetration Depth (Aluminum Alloy Series 1-3) 3MM 3MM 4MM 5MM Penetration Depth (Aluminum Alloy Series 4-7) 2MM 2MM 3MM 4MM Automatic Wire Feeding 0.8-1.6 Welding Wire 0.8-1.6 Welding Wire 0.8-1.6 Welding Wire 1.0-1.6 Welding Wire Total Machine Power Consumption ≤ 4.5KW ≤ 6KW ≤ 7.5KW ≥ 10KW Cooling Method Constant Temperature Water Cooling Swing Mode Single Swing / Double Swing (Optional) Robot Arm Length Options 1440mm/1730mm/2010mm Product Features

1. Adjustable Welding Width

The laser spot swing width can be adjusted up to 5mm, effectively compensating for material feeding errors.

2. Communication and Laser Welding System

Through our independently developed Macro program, real-time calling and changing of output power is possible. The robot, laser, and welding torch are perfectly compatible, achieving dual swing 9-axis synchronized control to meet complex or high-demand process requirements.3. Precisely Controllable Wire Feeding System

Accurate wire feeding control has always been a challenge in traditional laser welding. Ideal welding processes require wire feeding only after the arc starts and the molten pool reaches a certain state; otherwise, the arc formation cannot be controlled. Wire feeding should gradually decrease and stop in advance during arc ending to ensure good arc termination and reduce wire sticking. Our independently developed LWS system controls whether to feed wire during welding and precisely controls the wire feeding speed, perfectly solving the stability and accuracy issues of wire feeding in laser welding.4. Wire Sticking Alarm (Optional)

Wire sticking caused by improper settings will automatically trigger our independently developed WSAS system, immediately stopping the machine to protect the laser torch and wire feeding device.5. Advantages of Laser Welding

Fast welding speed, minimal deformation, high weld quality. Suitable for welding carbon steel, stainless steel, aluminum, copper, titanium, and other metals. High welding flexibility with long-distance non-contact welding capability.

Application Industries

Automotive parts, motorcycle components, sports equipment, medical devices, household appliances, and other industries.

Application Cases

Previous Page

Previous Page